Platinum On Silica

Cas No: 7440-06-4

Molecular formula: Pt /Si2O3

Carrier: silicon oxide

Application scope:

catalyst

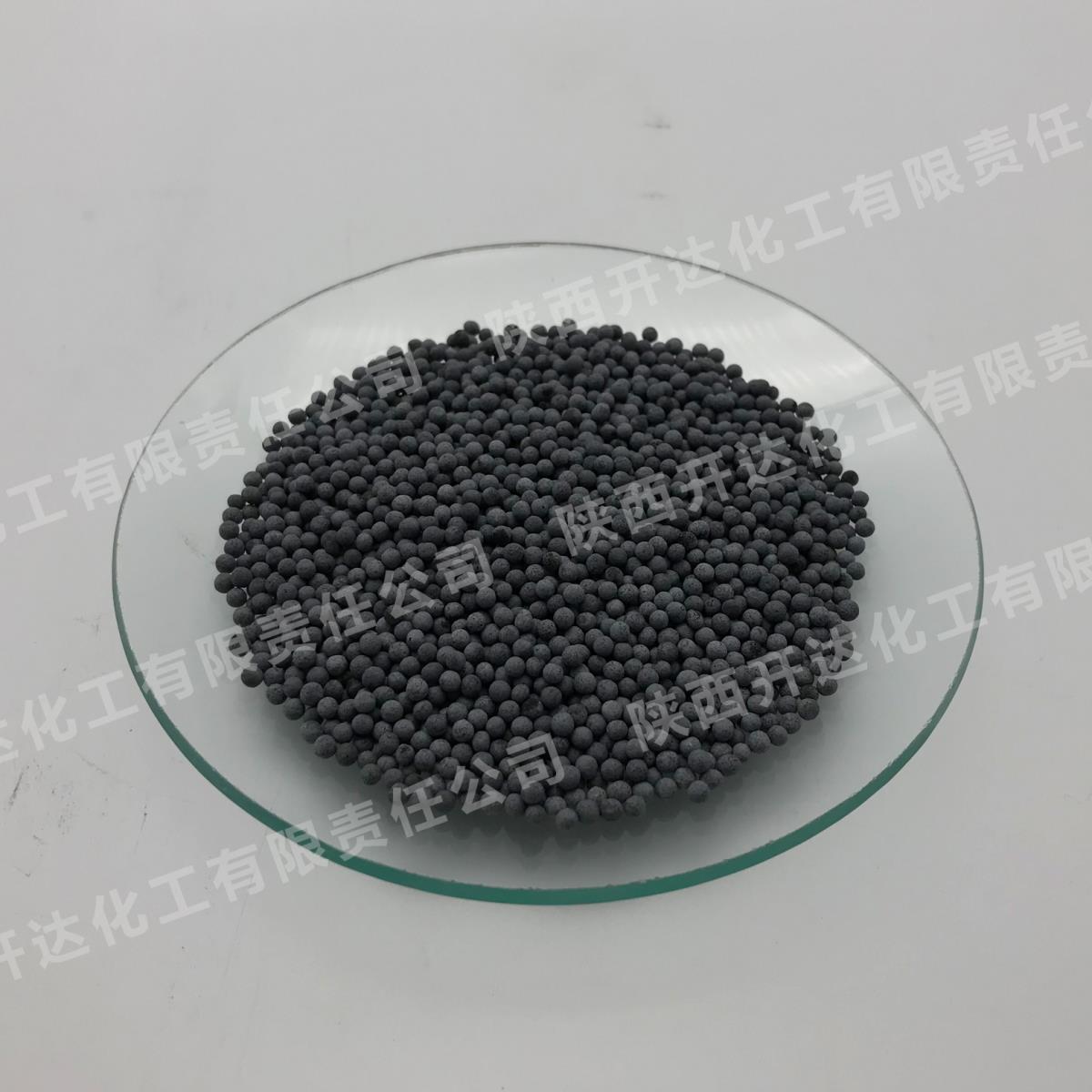

With aqua regia dissolving the treated platinum ore concentrate or electrolytic copper, nickel anode slime, after a series of chemical treatment, can get chloroplatinic acid ammonium, burning slowly by 1000 ℃, it will decompose made platinum sponge. Platinum is used as a catalyst in chemical reactions such as hydrogenation, dehydrogenation, isomerization, cyclochemistry, dehydration, dehalogenation, oxidation, and cracking, as well as in contact production of sulfuric acid, ammonia-oxidation production of nitric acid, ammonia and methane production of hydrocyanic acid, preparation of cyclohexane, and production of vitamins. The octane number of gasoline products can be improved by reforming naphtha with platinum catalyst. Platinum and its alloys are resistant to oxidation and corrosion at high temperature. Platinum and platinum-rhodium alloys are used as furnace wires and thermocouples in the metallurgical, glass and ceramic industries. Carrier type: fine pore spherical silica gel and fine pore block silica gel.

P&C parameters:

|

Pt content,wt% |

1%、5% |

|

Specific heat |

0.92kj/kg |

|

Specific surface area |

300~600m2/g |

|

The average particle size |

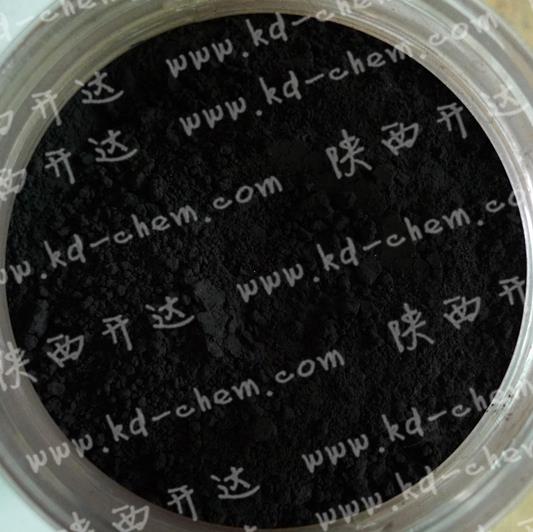

8.0~12.0um |

|

entrance |

0.8~1.1ml/g |

|

Particle size range |

125~425um |

|

Particle size qualification rate |

94.5% |

|

Wear rate |

<8.5% |

|

Silica content |

>98.5% |

陕公网安备 61030502000254号

陕公网安备 61030502000254号