Electrolytic copper foil

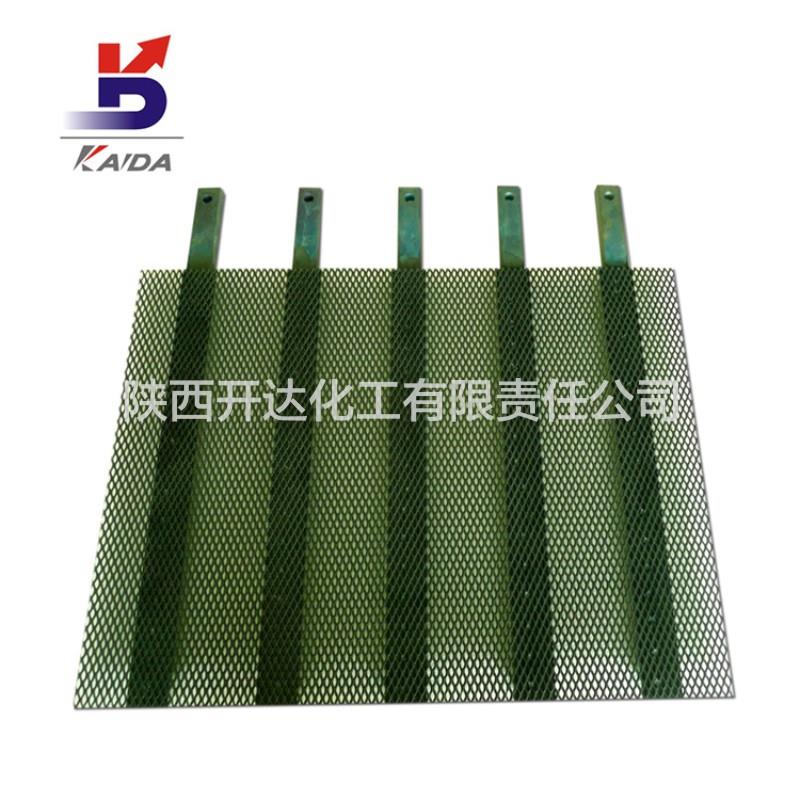

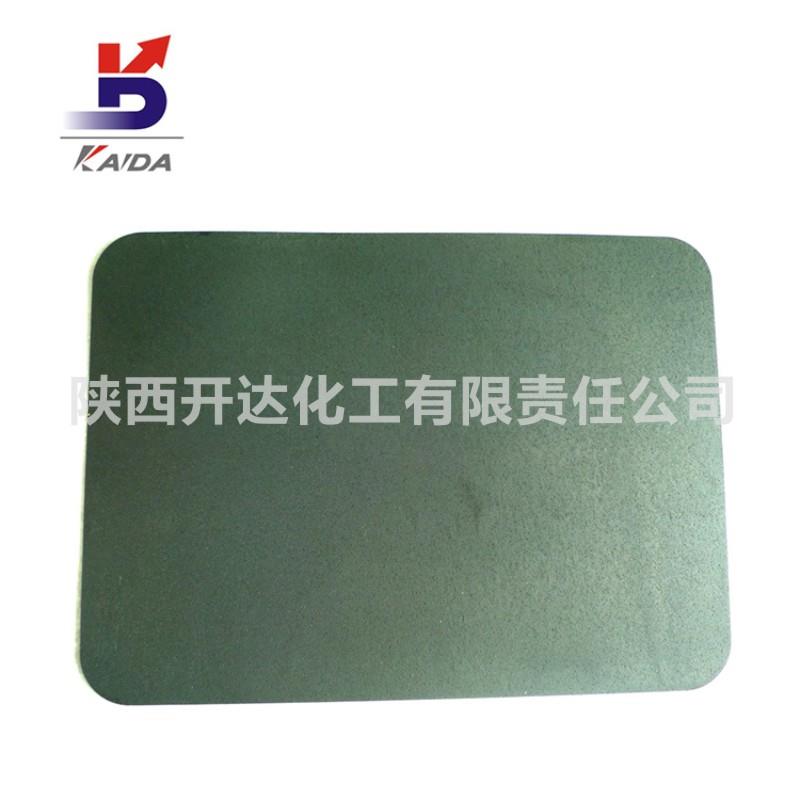

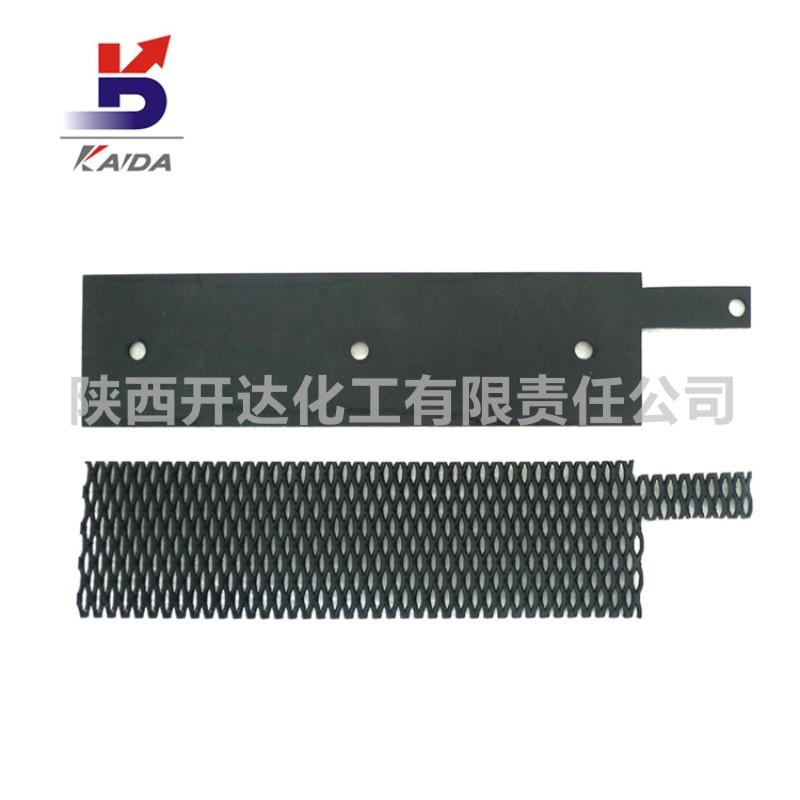

Application scope:

Electrolytic copper foil

1. Stable polar spacing

2, can improve the production capacity

3. High carrying current and uniform current distribution

4, no pollution on copper foil

5. Low energy consumption,Long working hours

陕公网安备 61030502000254号

陕公网安备 61030502000254号